leeb hardness testing of steel products|leeb hardness tester manual : consultant 1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C). The following are the advantages and disadvantages of Autoclave: Kills bacteria and spores – An autoclave destroys harmful bacteria and spores, ensuring a germ-free environment, crucial in medical and laboratory settings.

{plog:ftitle_list}

Max Temp 285˚F, Flat Seal, Coreless Roll – Autoclavable disposable waste bag of very strong PP-film with a broad seam at the bottom, for the sterilization and disposal of hazardous and contaminated labware.

1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C).

3.1.3 Leeb hardness test—a dynamic hardness test method using a calibrated instrument that impacts a spherically shaped tungsten carbide, silicon nitride, or diamond tipped body with a .

portable hardness tester for steel

portable hardness tester for metals

1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C).3.1.3 Leeb hardness test—a dynamic hardness test method using a calibrated instrument that impacts a spherically shaped tungsten carbide, silicon nitride, or diamond tipped body with a fixed velocity (generated by a spring force) onto a surface of the material under test.1.1 This test method covers the determination of the Leeb 3.1.5 verification—checking or testing the instrument to hardness of steel, cast steel, and cast iron (Part A), including ensure conformance with this test method. the methods for the verification of Leeb hardness testing. 4. Significance and Use. Leeb hardness testing is a dynamic and robust method employed for determining the hardness of steel products, cast steel, and cast iron. Governed by the ASTM A956/A956M standard, this method utilizes the Leeb hardness principle to deliver fast and accurate measurements essential in various applications, from quality control to on-site metal .

This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron, including the methods for the verification of Leeb hardness testing instruments, and the calibration of standardized test blocks.Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to impact velocity of a moving impactor is used to determine the hardness. ASTM A956 is a globally recognized standard employed for assessing the hardness of steel products using the Leeb rebound method. It provides guidelines and procedures for utilizing portable hardness testers to measure the hardness of . This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C).

1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C).The Leeb hardness test, ASTM A956, is a dynamic or rebound method that determines the Leeb hardness by comparing the rebound velocity to the impact velocity of a tungsten carbide ball or a diamond-tipped impact body. 1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C).

3.1.3 Leeb hardness test—a dynamic hardness test method using a calibrated instrument that impacts a spherically shaped tungsten carbide, silicon nitride, or diamond tipped body with a fixed velocity (generated by a spring force) onto a surface of the material under test.1.1 This test method covers the determination of the Leeb 3.1.5 verification—checking or testing the instrument to hardness of steel, cast steel, and cast iron (Part A), including ensure conformance with this test method. the methods for the verification of Leeb hardness testing. 4. Significance and Use. Leeb hardness testing is a dynamic and robust method employed for determining the hardness of steel products, cast steel, and cast iron. Governed by the ASTM A956/A956M standard, this method utilizes the Leeb hardness principle to deliver fast and accurate measurements essential in various applications, from quality control to on-site metal .

This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron, including the methods for the verification of Leeb hardness testing instruments, and the calibration of standardized test blocks.Determination of the hardness of metallic materials according to Leeb is defined in the ISO 16859 and ASTM A956 standards. In this dynamic test method, the ratio of rebound velocity to impact velocity of a moving impactor is used to determine the hardness. ASTM A956 is a globally recognized standard employed for assessing the hardness of steel products using the Leeb rebound method. It provides guidelines and procedures for utilizing portable hardness testers to measure the hardness of . This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C).

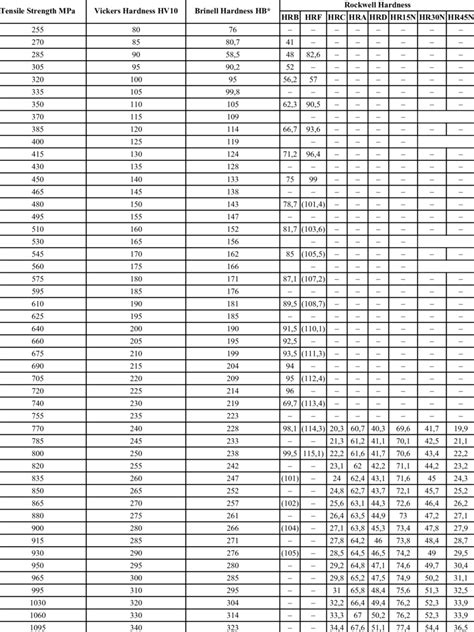

leebs hardness chart

1.1 This test method covers the determination of the Leeb hardness of steel, cast steel, and cast iron (Part A), including the methods for the verification of Leeb hardness testing instruments (Part B), and the calibration of standardized test blocks (Part C).

leeb hardness testing method

leeb hardness tester principle

leeb hardness tester manual

leeb hardness calculator

Autoclaved aerated concrete (AAC), a form of cellular concrete, is a low-density cementitious product of calcium silicate hydrates in which the low density is obtained by the formation of .

leeb hardness testing of steel products|leeb hardness tester manual